color case hardening at home

For a modern firearm color case hardening can create a unique one-of-a-kind gun. 100 Guarantee on Everything.

How To Do Color Case Hardening The Hobby Machinist

Classic Case Colors LLC.

. While experimenting with aging steel and seeing what can be done with various chemicals I accidentally learned that a Cold Blue solution can be used to simul. Color case hardening is dependant to a degree on the steel but more on the combination of materials used in the procedure and how they are arranged. Here at Tyler Gun Works we are able to Color Case items others cant due to our ability to work at lower temps.

Ad Highest Ranked Gunsmithing Site on the Web. Throughout history no doubt many different compounds were tried in a quest to improve the process and perhaps obtain better colors. Color case parts with their subtle shades of blue gray and straw really give a gun a true custom look.

Ad Improve The Wear Properties Of Your Parts With Vacuum Carburizing. And Any Size You Choose is15 Off. Solar Atmospheres Processes Various Steels and Many Other Materials.

The theory is this. Here at Lohman Gunsmith we are able to bring those faded colors back by redoing the color case hardening. When low-carbon steel reaches a certain temperature the carbon in.

Color case hardening is usually done with a combination of wood charcoal bone and leather charcoal and a couple other secret ingredients depending on the operator. Please email Howell Arms so we can provide you with a preliminary quote prior to shipping. Most of the newer receivers made today are made of pre-heat treated steel.

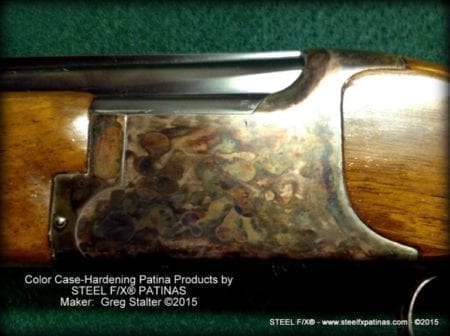

Bone charcoal case hardening takes a good deal of time with parts needing to be carefully packed into a case of charcoal and heated carefully up to the neighborhood of 1300 to 1400 degrees Fahrenheit. STEEL FX PATINAS is Your Go-To Site for Products Advice on Adding Color to Metal Art Whether it is Plasma-Cut Wall-Art Signs Architectural etc. To case harden a part it is first cleaned.

The box containing the part and carbon is then heated to a red heat 1700F - 1800F 830C - 980C. I suspect that it is activated charcoal. This is the ONLY Gel Patina in This Build Your Own Kit That is NOT Optional.

Ad Find Deals on case hardening compound in Craft Supplies on Amazon. Color case hardening is case hardening. You can get it at your pet shop.

On a side note high carbon steels can be colored using the color case hardening process it serves no real useful purpose other than putting the colors on the part but it can be done. The container is closed and sealed with clay to keep out air. At Lohman Gunsmith we use our special formula depending on the type of metal we use a combination that includes bone and or charcoal plus a few other things.

Afterwards the parts were removed from the furnace and quenched. The end result is no different in surface hardness or depth of case than non-color case hardening. Most early formulas mentioned in gunsmithing texts do suggest that the use of bone wood and leather charcoal was common.

One of the secrets of good color case hardening is the type of charcoal used. The resulting shell of hardened metal can be as much as 006 of an inch deep though care must be taken. At last a convenient easy-to-use process to help the gunsmith create beautiful genuine color case hardening.

06-20-2013 1145 AM. We keep our temperatures below hardening temperatures. Color case hardening sometimes referred to as case-hardening case color hardening or surface hardening is a heat treating process and one of the earliest ways of hardening lower-grade steel.

The process results in a marbleized coloring of the parts and provides a thin hardened layer of steel while preserving a softer steel core. Many old guns have faded color case hardening. The best carbon for case hardeningand one that will give a DEEPER CASE than KaseniteCherry Redor other carbonaceous sources is AQUARIUM CHARCOAL.

I generally polish to at least 320 grit by hand before starting the case hardening operation rougher surfaces will produce more muted colors. Knife blades like this and others that I do also have to be properly blocked to help prevent warpage which generally will occur on thin sections without prior planning. Nice writeup on the case hardening procedure and heat treat oven build.

The process of bone charcoal color case hardening involves taking the part and packing it in a combination of wood charcoal and bone charcoal in a stainless steel crucible. We use the traditional wood and bone charcoal method of color case hardening. IRT the color case hardening I found packing the part in a mixture of hand ground dry cow or horse bone my preference being the latter and Hickory wood charcoal dust gives the richest most colorful spectrum Also the pattern can be varied by how you quench the cherry red part every manufacturer used a different method Stevens would randomly use a jerking motion.

It Will Produce a Range of Colors from Yellow-Gold to Grays Blue-Grays Various Shades of Blue. Plus renewed interest in the old west has brought many old and well used guns out of. The process leaves a hard.

Originally this process used bone charcoal heated to an exact temperature. BLUE HALO Gel Patina is The Single Most Important Gel Patina for the Color Case-Hardening Look. To case harden a part the finished low-carbon steel part is heated and then packed with a high-carbon compound like Rose Mills Cherry Red instant hardening compound.

WE ARE A FEDERALLY LICENSED FIREARMS MANUFACTURING AND REPAIR FACILITY LOCATED IN SCENIC NORTHERN IDAHO SPECIALIZING IN THE FAITHFUL RESTORATION OF GENUINE BONE CHARCOAL COLOR CASE HARDENING RUST BLUING AND HAND RUBBED OIL FINISHES ON VINTAGE AND ANTIQUE SPORTING ARMS. Color Case hardening is getting very popular. Following the operation they need to be tempered and as long as you dont go much beyond 450 degrees F you wont mess up the colors in fact I generally draw.

Then that package is placed into a high temperature furnace. Then it is packed in a steel clay or graphite container with ground charcoal. Working at low temps gives us the ability to bring you the colors you deserve without double heat.

Full of millions of tiny holes to let the CO2 gas out better to go into the steel.

Color Case Hardening Shooting Sportsman Magazine

American Handgunner When You Re Hot American Handgunner

A Way To Color Case Harden At Home Gunsamerica Digest

Color Case Hardening Patina Kit

Color Case Hardening Turnbull Restoration

Color Case Hardening Effect Using Cold Blue Youtube

Here S Something You Just Don T See Everyday Color Case Hardened Les Baer 1911 Firearm Addicts

American Handgunner When You Re Hot American Handgunner

American Handgunner When You Re Hot American Handgunner

How To Color Case Harden Presented By Larry Potterfield Midwayusa Gunsmithing Youtube

Color Case Hardening A Parker Shotgun Midwayusa Gunsmithing Youtube

Blue Halo Polymer Gel Patina For Color Case Hardened Effect On Steel Iron Case Hardened Color Patina

Praxair Color Case Hardening Kit Brownells

Color Case Hardening Case Hardened Tactical Metal

Color Case Hardening Patina Kit

Do It Yourself Color Case Hardening Patinas Procedures For Guns Gun Parts Knife Blades Youtube